A square-inspired design for kitchen shelves

This blog is a portfolio of bespoke shelving solutions.

My name is Tom Morrell. I am a musician and craftsman, based in Wiveliscombe.

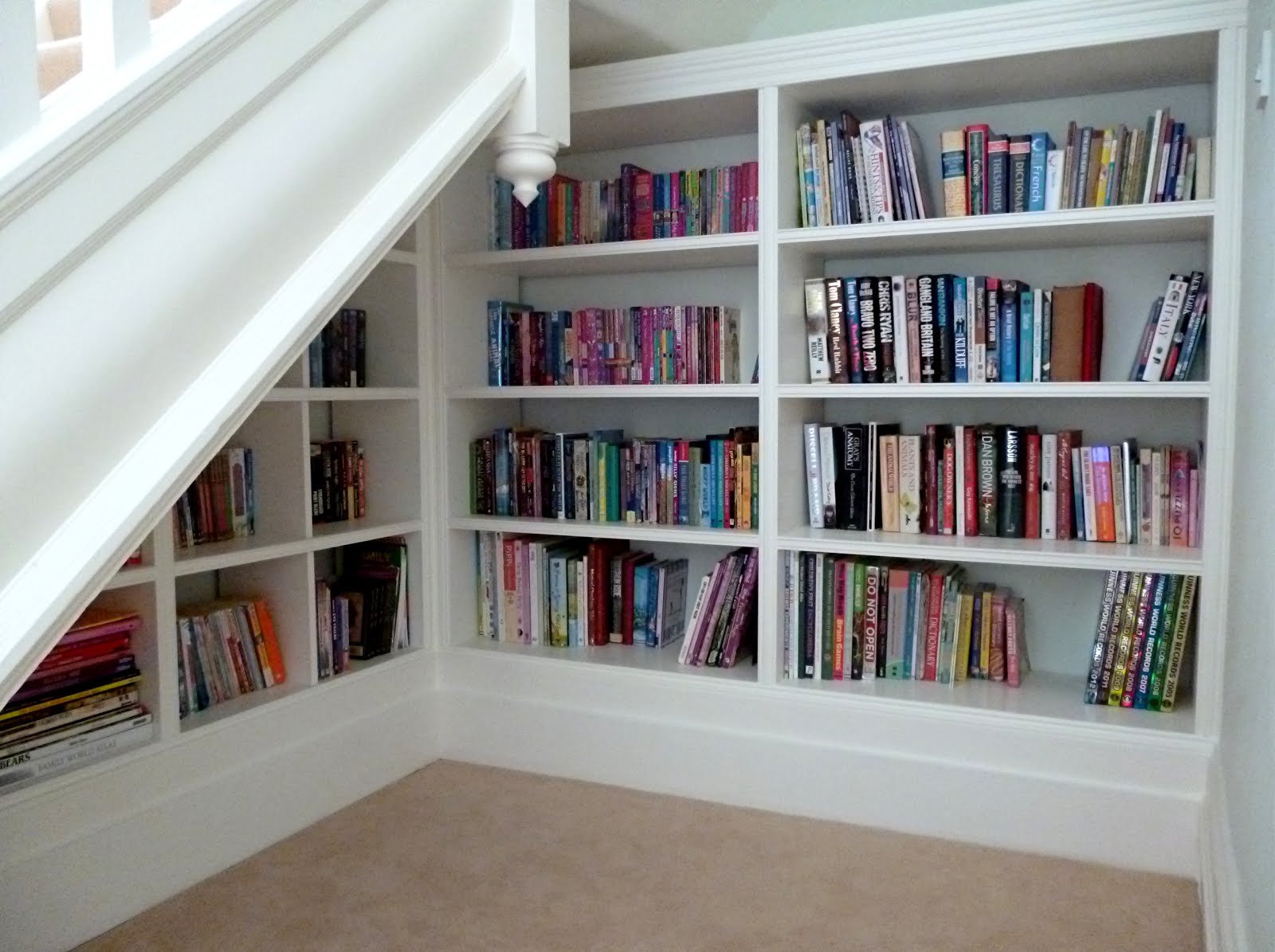

BESPOKE BOOKSHELVES

I can help you to make the most of the space in your home or workplace with elegant storage, built to your specifications.

DESIGN

I start each project by visiting your space, measuring up and then producing a 3D design, so you know exactly what we're planning. We need to agree that it will be just right for you and for the room.

EXPERT INSTALLATION

The next stage is to produce more detailed design drawings, a cutting list and an estimate of the cost. I install the job myself, using the most appropriate materials, with the minimum of mess and noise. I make sure that your installation looks great, works well and lasts for ever!

email: t.morrell@uwclub.net

facebook: https://www.facebook.com/BespokeBookshelves

telephone: 01984 624496

"Tom's creativity is exceptional. I am grateful for the skill

and application with which he designed, fitted and then painted

different units in my cottage where space is limited and walls are

crumbling and lumpy! Even better, Tom leaves everything clean and tidy at

the end of each day. I am delighted with the end result and can at last

house all my books, CDs and clutter".

Mrs R

I would not hesitate in recommending the work of Tom

Morrell. His thoughtful understanding of his customers' individual requirements

and his excellent craftsmanship in the finished article are outstanding.

Jonquil Alpe

Tom hand crafted a picture frame for me identical to another one [one of

my favourite art nouveau pieces]. Almost impossible to tell difference between

new one and original. I would certainly use his services again and definitely

recommended.

Roger W., Wiveliscombe

Dear Tom, The builders left and you came. You filled the various empty spaces with beautiful cupboards and shelves and our house was completed. Thank you so much for the care, design and solid craftsmanship you put into the many projects we asked you to carry out. Your constructions and painting remain most appropriate and will last for many years and............we really missed you when you had gone.

Mike B

Tom’s design perfectly fitted the bill. Solidly built and beautifully finished

off.

Jane and Jeff

I enjoy designing and constructing high quality bookcases and shelves. Each installation presents a challenge - a puzzle to be solved. The answer will be the design that does its job properly and looks right in the room!

I also make musical instruments, play sets, shop counters, bars, cupboards, stairs, doors, partitions and all kinds of objects in wood and metal.

I designed all the installations you see here, except for the organs and organ components.

telephone me at:

01984 624496 or 07976 288381

email me at:

t.morrell@uwclub.net

facebook page: